包含印刷電路板、軟板、IC載板與封裝、HDI、陶瓷基板…等電子產業自動化設備與整廠物流規劃與智能自動化整合服務

包含雷射技術應用設備與TFT-LCD、LED、Touch Panel、導光板…等產業之自動化與整廠物流、資訊整合之規劃與服務

提供半導體晶圓代工廠、DRAM廠等IC製造以及後段IC封測產業完整的無塵室倉儲設備、自動化與整廠物流規劃,以及智能自動化整合服務

包含無人小車AGV/RGV、倉儲整合系統、系統智慧控制、韌體設計與控制、物流通訊控制,以及視覺系統設計等產業自動化系統整合規劃與物流整合服務。

SB-101 30 pcs. Flip Cooler

PCB 自動化適合所有需冷卻、靜滯、翻板或檢視之製程

PCB 自動化適合所有需冷卻、靜滯、翻板或檢視之製程

SB-300 Double Conveyor Flipper

適合于所有 PCB 自動化需要翻轉硬板,如带式打磨机

適合于所有 PCB 自動化需要翻轉硬板,如带式打磨机

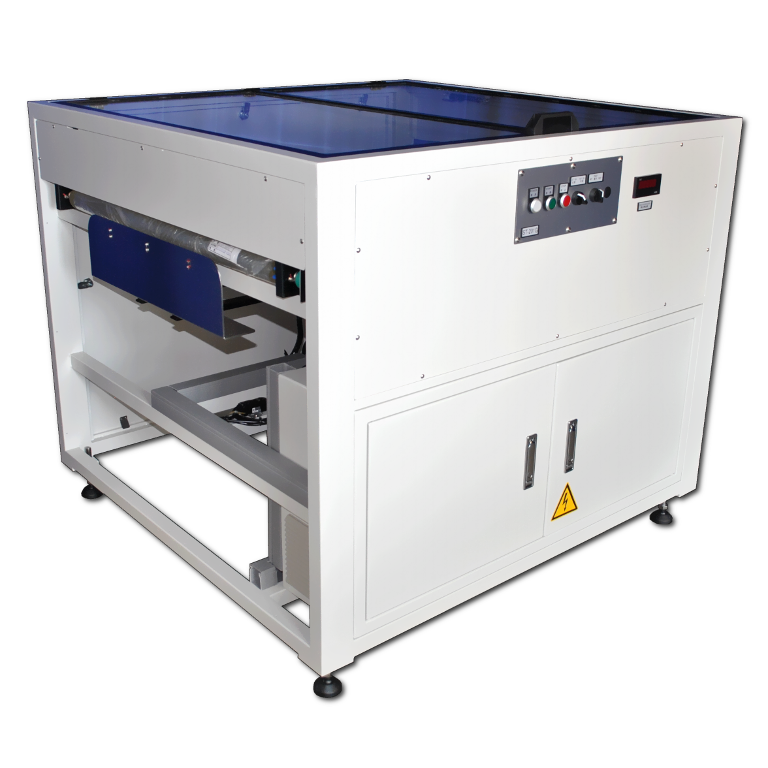

SB-308A Flip Machine

PCB 自動化適用于在進程中對面板做出旋轉的動作

SB-503 Buffer Machine

適合各式聯線需暫存或緩衝之製程

適合各式聯線需暫存或緩衝之製程

SC-101 Positioning Machine

PCB自動化適合在進程中改變板子的排列

SLR/SUR-246 Automatic Loader / Unloader

PCB自動化適合在不同處理過程裝載和卸載而不用阻焊膜

PCB自動化適合在不同處理過程裝載和卸載而不用阻焊膜

SLR/SUR-246P Automatic Loader / Unloader

PCB自動化適於裝載和各種處理而不用阻焊膜,或從不同的預設角度箱或盒的卸載

PCB自動化適於裝載和各種處理而不用阻焊膜,或從不同的預設角度箱或盒的卸載

ST-103 4-way Panel Diverter

適用各聯線之製程及需作轉角處

適用各聯線之製程及需作轉角處

ST-201 Panel Rotator

PCB自動化適合在處理過程之間旋轉剛性板

PCB自動化適合在處理過程之間旋轉剛性板

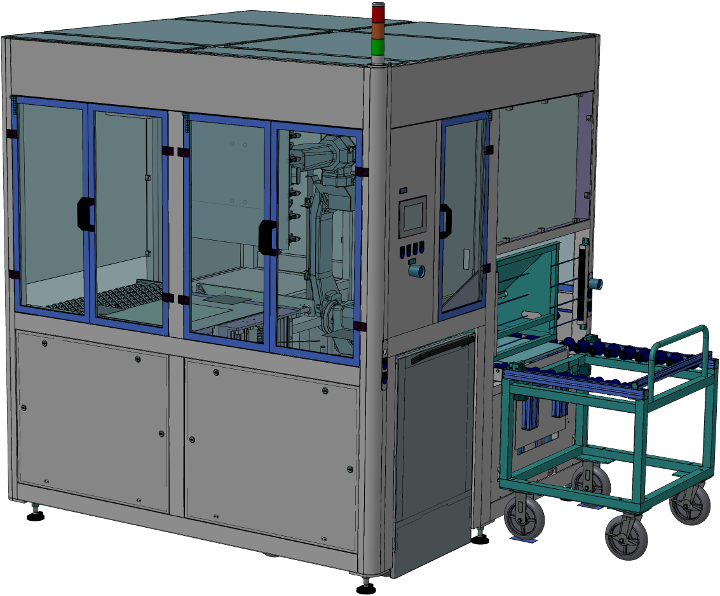

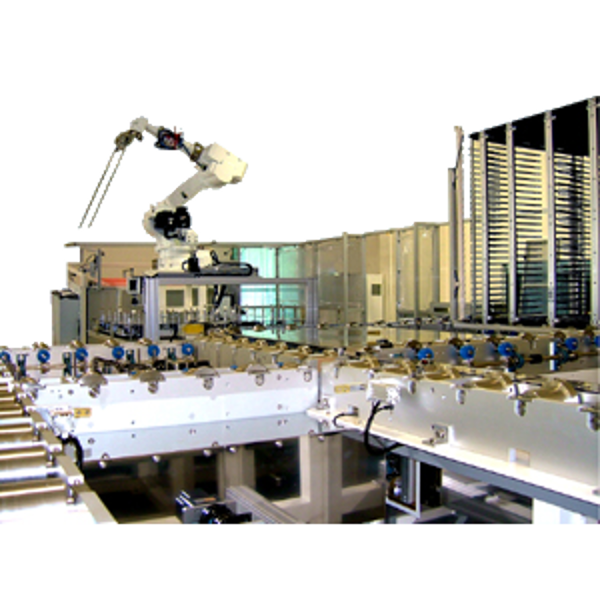

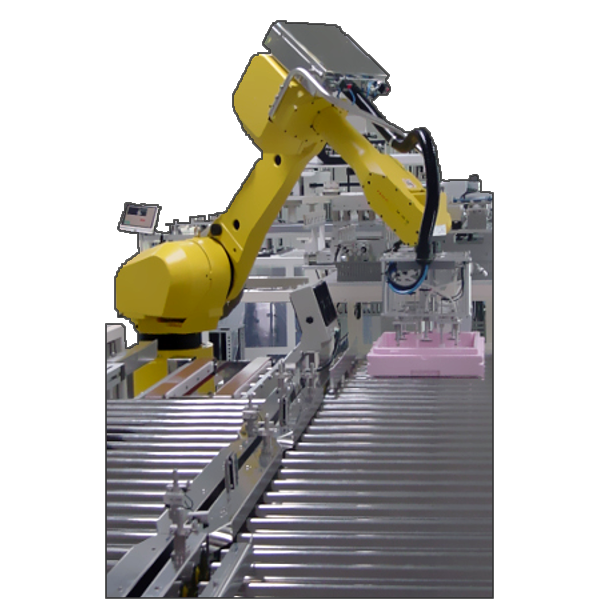

SLR/SUR-628C 6-axis Handler Robot

PCB自動化適於從單個托盤的裝載/卸載面板

SLR-632 Loader/Unloader for AOI/DI processes

PCB自動化適合處理在AOI/ DI過程中需要翻轉的面板

PCB自動化適合處理在AOI/ DI過程中需要翻轉的面板

SUR-128 Double tray / magazine unloader

PCB自動化適合把面板卸載到托盤或L架

PCB自動化適合把面板卸載到托盤或L架

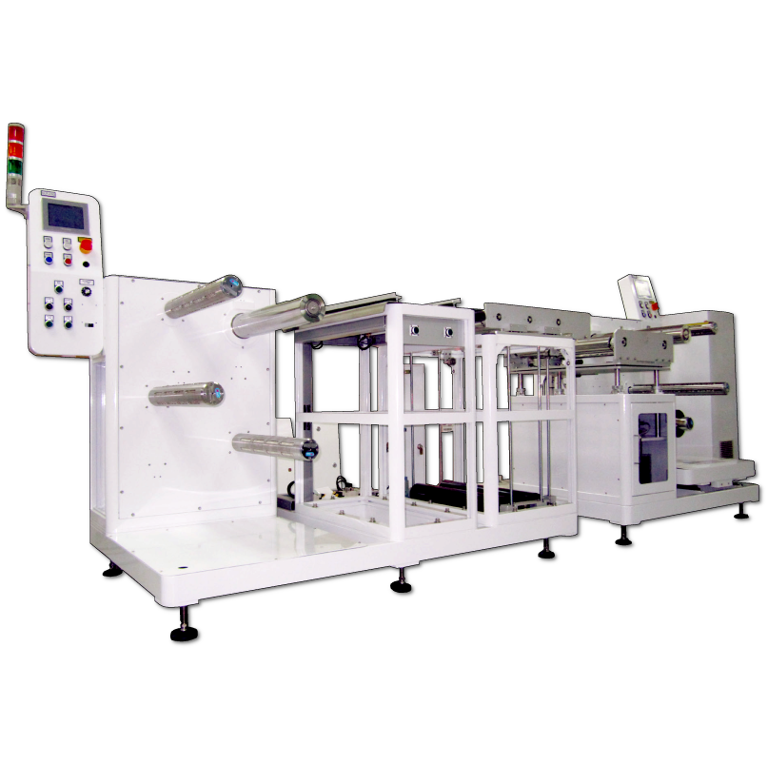

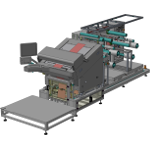

SLF/SUF-200A Roll-to-roll

適合DES製程單列寬幅500mm或250mm材料, 捲對捲連續性作業

適合DES製程單列寬幅500mm或250mm材料, 捲對捲連續性作業

SLF/SUF-230 DES wet process

適用於濕製程單列寬幅500mm或250mm材料, 捲對捲連續性作業

適用於濕製程單列寬幅500mm或250mm材料, 捲對捲連續性作業

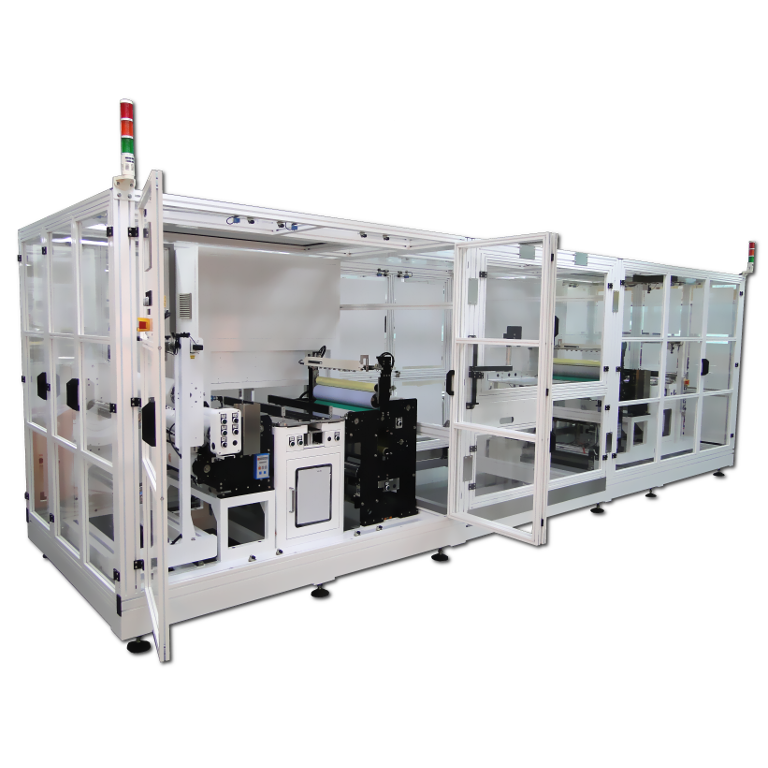

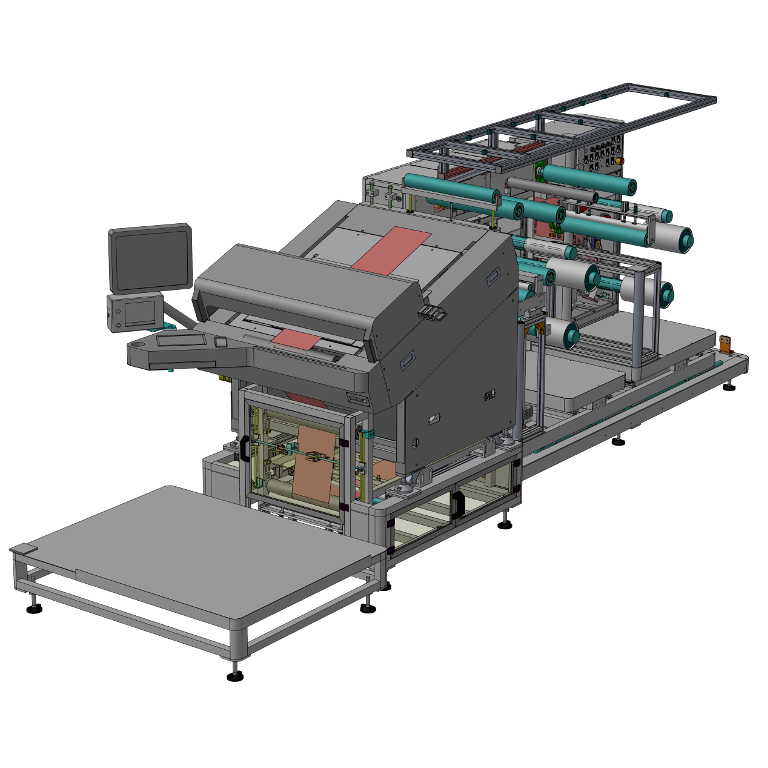

SLF/SUF-300D/300E Roll-to-roll handling system

適用於AOI製程單列寬幅500mm或250mm材料, 捲對捲連續性作業

適用於AOI製程單列寬幅500mm或250mm材料, 捲對捲連續性作業

SLF/SUF-233 Roll-to-roll handling system

適用於濕製程單列寬幅500mm或250mm材料, 捲對捲連續性作業

適用於濕製程單列寬幅500mm或250mm材料, 捲對捲連續性作業

SLF/SUF-310A Roll-to-roll handling system

適用於雷射鑽孔製程單列寬幅500mm或250mm材料, 捲對捲連續性作業

適用於雷射鑽孔製程單列寬幅500mm或250mm材料, 捲對捲連續性作業

SLF/SUF-350C Roll-to-roll handling system

適用於VRS單列寬幅500mm或250mm材料, 捲對捲連續性作業

適用於VRS單列寬幅500mm或250mm材料, 捲對捲連續性作業

SVF-200/200A for Yamaha punching system

適用於 YAMAHA-FC602 L2/S2單板作業收放板

適用於 YAMAHA-FC602 L2/S2單板作業收放板

FP-100 Dense Packer System

Loader/Unloader system suitable for packing or unpacking TFT substrates into or from transport boxes.

Loader/Unloader system suitable for packing or unpacking TFT substrates into or from transport boxes.

FP-101 Dense Packer System

Loader/Unloader system suitable for packing or unpacking TFT substrates into or from transport boxes.

Loader/Unloader system suitable for packing or unpacking TFT substrates into or from transport boxes.

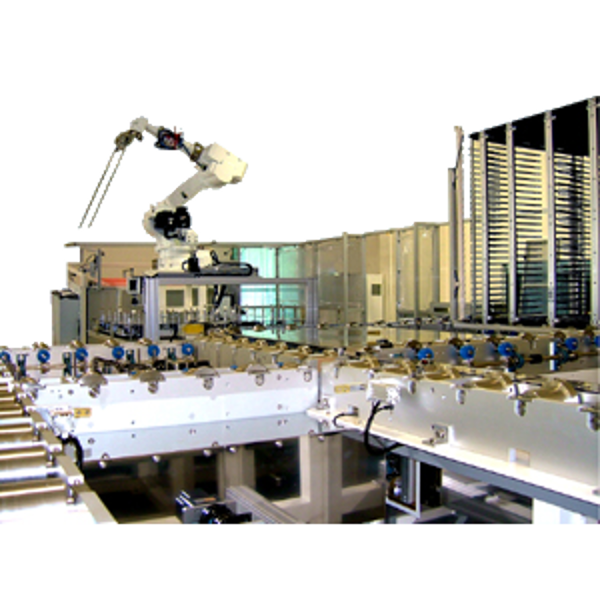

FL/FU-100 Loader/Unloader system

Loader/Unloader system suitable for loading and unloading TFT substrates into and from the manufacturing line.

Loader/Unloader system suitable for loading and unloading TFT substrates into and from the manufacturing line.

FP-200 Cell CF Packer/Unpacker System

Packing/Unpacking system suitable for packing or unpacking TFT substrates into or from transport cassettes.

Loader/Unloader system suitable for packing or unpacking TFT substrates into or from transport cassettes.

FP-106 Dense Packer System

Loader/Unloader system suitable for packing or unpacking TFT substrates into or from transport boxes.

Loader/Unloader system suitable for packing or unpacking TFT substrates into or from transport boxes.

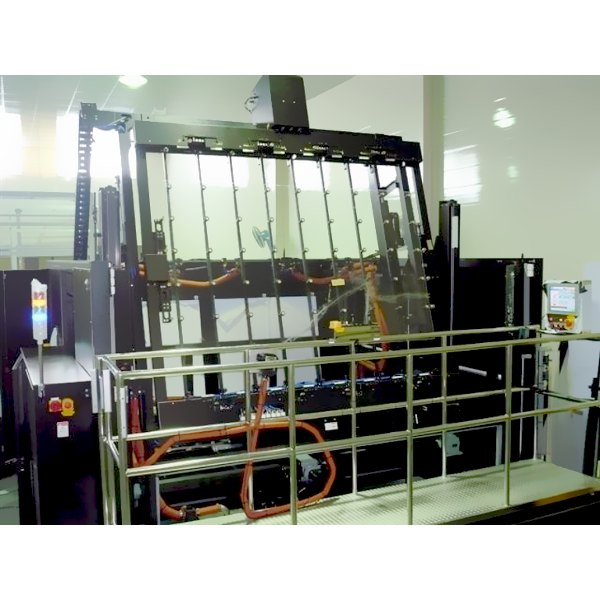

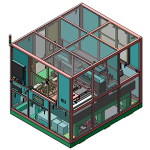

FV-102 Loader/Unloader system

Suitable to inspect TFT substrates visually from different angles to identify defects and scratches.

Automation system suitable to inspect TFT substrates visually from different angles to identify defects and scratches.

FLS-100 Laser short ring cut

Suitable to interrupt electrical circuits on TFT substrates.

Automation Laser system suitable to interrupt electrical circuits on TFT substrates.

Wafer Carrier Stocker

For the different storage needs of cleanroom space planning, SAA can provide standard stocker as well as ZIP stocker for storing carriers, including 300mm FOUP and 200mm SMIF Pods.

For the different storage needs of cleanroom space planning, SAA can provide standard stocker as well as ZIP stocker for storing carriers, including 300mm FOUP and 200mm SMIF Pods.

Reticle Carrier Stocker

For the different storage needs of cleanroom lithography area space planning and process requirement, SAA can provide standard stocker as well as ZIP stocker for storing carriers, reticle pod, reticle box, and EUV pod.

For the different storage needs of cleanroom lithography area space planning and process requirement, SAA can provide standard stocker as well as ZIP stocker for storing carriers, reticle pod, reticle box, and EUV pod.

Backend Carrier Stocker

For cleanroom space planning in the IC backend packaging and testing, SAA can provide standard stocker as well as ZIP stocker for storing carriers, including Tray Cassettes and Magazines.

For cleanroom space planning in the IC backend packaging and testing, SAA can provide standard stocker as well as ZIP stocker for storing carriers, including Tray Cassettes and Magazines.

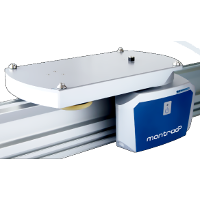

Montrac® RGV

This Rail-Guided Vehicle is suitable to link different processing stations by mens of a light and compact monorail system and fast, efficient, self-propelled shuttles.

This Rail-Guided Vehicle is suitable to link different processing stations by mens of a light and compact monorail system and fast, efficient, self-propelled shuttles.

AGV L1200S

Automatic Guided Vehicle system suitable for transporting a load up to 1.2 tons in any operational environment, also in combination with traffic of people and industrial trucks.

Automatic Guided Vehicle system suitable for transporting a load up to 1.2 tons in any operational environment, also in combination with traffic of people and industrial trucks.

Mobile Robot (MR)

The mobile robot comprises an AGV and a six-axis robotic arm. With a reliable safety design, the AGV can work with personnel or perform tasks independently.

The mobile robot comprises an AGV and a six-axis robotic arm. With a reliable safety design, the AGV can work with personnel or perform tasks independently.

Overhead Conveyor (OHCV)

The OHCV offers high transfer speeds and a zero footprint, effectively connecting OHT and other machines, such as cross-floor lifts.

The OHCV offers high transfer speeds and a zero footprint, effectively connecting OHT and other machines, such as cross-floor lifts.

RGV自動化物流搬運系統

RGV搭配多項自動化設備如倉儲、升降機等各式搬運機構,並整合於SAA iLIS智慧搬運整合系統,隨時掌握全線物流動態

AGV自動化物流搬運系統

多樣潛伏舉升型、叉取型等AGV產品,可智慧路徑規劃、偵測及避障等動態性能,並搭配SAA iLIS智慧搬運整合系統,以實現全線自動化稼動。

iLIS智慧物流搬運系統

高度整合智慧物流多項系統與功能,自動化管理生產線,並實時監控產線動態

MCS 物料管理系統

優化、監控和控制製造過程中物料的流動,旨在提高物料利用率、降低庫存成本、優化生產計劃並確保供應鏈的順暢運作。

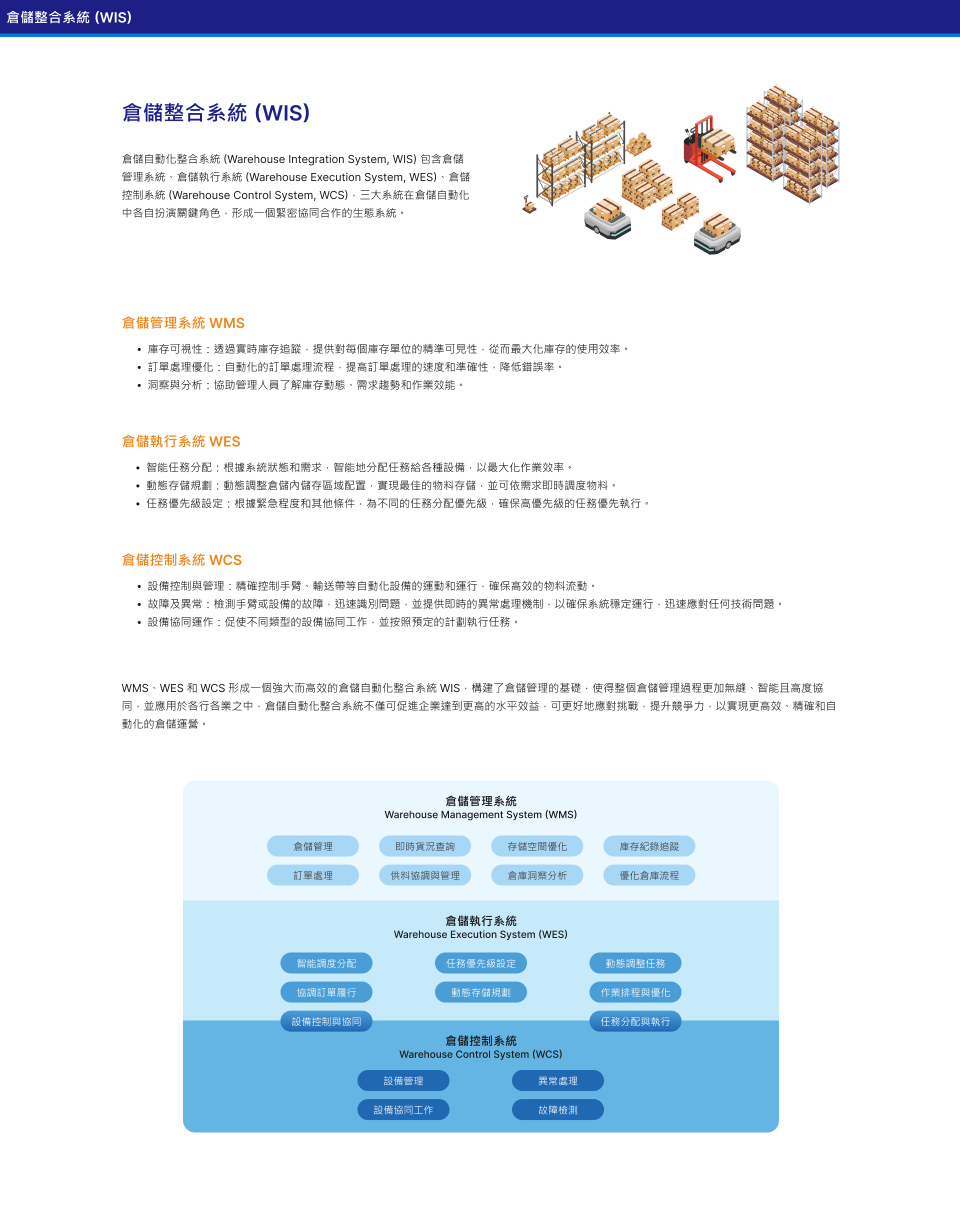

WIS 倉儲整合系統

為一綜合的倉儲整合解決方案,專注於優化和管理倉庫內的庫存、訂單處理和作業流程。

FMS 車隊管理系統

有效協調和監控小車的運行,智慧路徑規劃及車輛檢測可提升效率、安全性並實現成本控制。

EDM 戰情顯示系統

即時監控和管理車輛、倉儲、手臂等設備的運行狀況,實現對設備運用效益的即時評估,同時支持生產排程和物流規劃的決策。